IVE™ - IRONCLAD VISUAL ENGINEERING

Posted by IRONCLAD PERFORMANCE WEAR on Jun 11th 2019

For IVE™, our goal was to gain valuable knowledge about “what contrast is”, and “how it works in an industrial setting.” We gained valuable knowledge in different areas, such as color, contrast, perception, motion, and physiology to better understand what we needed to focus on in order to improve hand protection in the harshest environments.

Through our research, we identified that High Visibility isn’t simply a matter of using a fluorescent colors. We had to consider the use of color in the environment in which it is being used. All of this information and research led us to IVE™-Ironclad Visual Engineering. All of the colors, shapes, and materials of IVE™ have been evaluated to provide optimal visibility as it pertains to three key aspects:

- 1. Brightness

- 2. Recognition

- 3. Contrast

WHY ARE FLUORESCENT COLORS SO BRIGHT?

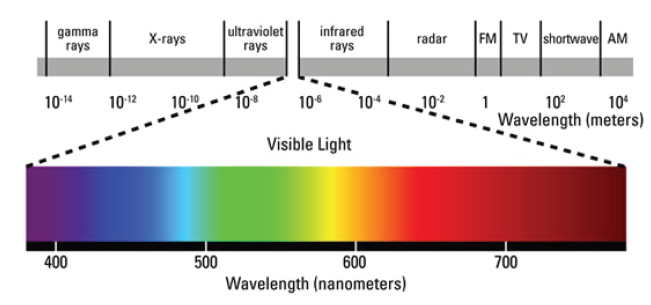

The color spectrum is much larger than our eyes can perceive. The range moves from low-energy infrared rays to high-energy ultraviolet rays. The visible light spectrum, or the colors that the human eye can actually see, are actually in the middle of the range.

Normal color absorbs and re-emits a portion of the visible spectrum that matches its principal wavelength, while the remaining colors are absorbed. Fluorescent colors use a larger amount of both the visible spectrum and the lower wavelengths compared to conventional colors. They not only absorb and convert light energy of the dominant wavelength, but also the wavelengths of ultraviolet rays and other colors lower in the visible spectrum. As a result, your eye perceives a far more intense color. Where a clean, bright conventional color is able to reflect a maximum of 90% of a color present in the spectrum; a fluorescent color can reflect as much as 300%.

PERCEPTION AND RECOGNITION DISTANCE

High visibility products have been proven and mandated all over the world. The advantage of fluorescent gloves is that they increase the distance when an object is seen. Some studies show that fluorescent clothing is five times more visible than conventional clothing. However, there is a fundamental difference between being seen and being recognized. If an operator can not only see color, but can also identify your hands, they can better plan their own maneuvers, which should lessen the opportunity for a recordable hand injury. We were conscious of what operators were able to detect, specifically the critical elements of both perception and recognition at a distance.

PERCEPTION DISTANCE - is the distance from where an object is first seen. During this time the brain processes a lot of information to decipher what the object is. The result is based on familiar patterns and past experiences, but ultimately the object may not be accurately recognized. The inability to recognize the hand, and/or the hand signal that has been given, could lead to a judgment call-which could lead to a recordable hand injury.

RECOGNITION DISTANCE - is the distance where the brain can perceive what the object actually is. By using prior knowledge and interpreting visual clues, such as colors, contrast, distance and motion, the brain is more likely recognize the object.

As previously mentioned, fluorescent colors are easier to see. However, through our research we identified that advantages could be gained by considering all possibilities to increase perception and recognition distances to further improve visibility and hand safety.

CONTRAST

One of the most important factors effecting visibility is contrast. Contrast gives the brain visual clues, ultimately resulting in an earlier and informed decision on the identity of an object. We know that contrast between the back of hand and the palm has been requested in our oil and gas gloves historically. There are basically two types of contrast, which can be explained by the prominence of a color compared to its background and the difference in a color to adjacent colors, i.e. color intensity and difference. To find the right approach we considered the changing backdrops that are present on the oil rig and in the dry oil patches. The result is the IVE™ Icon. In an environment with numerous horizontal and perpendicular lines are present (cranes, scaffolding, steel pipes etc.) a more rounded design that incorporates more angles than those that exist in the environment become more easily recognizable. When fluorescent colors and negative space are added (the center of the IVE™ icon), the shape becomes even more recognizable. The result is a shape that can be easily detected from further distance. This assures that the operators cannot only see the hands better, but they can also recognize the difference between the palm of the hand and the back of the hand. In an environment where hand signals are used, this level of distance recognition should result in fewer recordable hand injuries.

HAZARD STRIPES

Hazard stripes are also a valuable part of IVE™. Black and Yellow hazard stripes are the protocol for potential physical hazards ANSI Z535, and OSHA regulations 1910.22 and 1920.144. By utilizing these proven hazard strips on all of the fingertips, the goal is for the mind to immediately recognize that there is a “high probability of physical hazard” in this key area. With pinched and fractured fingers being two major recordable hand injuries: bringing visibility to these critical areas will make them easily recognizable and should decrease the opportunity of a recordable hand injury.