UNDERSTANDING DIFFERENT GLOVE MATERIALS

Posted by IRONCLAD PERFORMANCE WEAR on Aug 15th 2023

In the vast expanse of industries ranging from automotive repair and construction to the frontline healthcare, gloves stand as an essential line of defense. They protect workers' hands from the harsh elements of the workplace, be it sharp objects, vibration & impact force, hazardous chemicals, extreme temperatures, or harmful pathogens. With the right glove selection, the incidence of hand injuries can be drastically reduced. But how do we identify what constitutes the 'right glove'?

Understanding the selection of gloves goes beyond just the size and fit; it delves deep into the heart of the glove itself - the glove material. Selecting an appropriate glove material is a nuanced process, for each material comes with its unique set of properties, benefits, and potential limitations. The glove material directly impacts the glove's protective qualities, tactile sensitivity, and the comfort of the wearer's hands.

However, navigating the realm of glove materials can be quite a daunting task. There are various factors to consider - from the nature of the task at hand to the possible risks associated, the choice of glove material can make all the difference between safety and a potential hand injury.

This is where Ironclad Performance Wear steps into the picture. As a pioneer in the world of high-performance, task-specific work gloves, we've spent years researching, innovating, and perfecting our products to provide superior hand protection. Our passion for advanced material science, coupled with a focus on design and durability, allows us to deliver gloves that not only meet but exceed industry expectations.

Whether you're working in extreme temperatures, handling hazardous material or dealing with sharp objects, Ironclad is dedicated to creating gloves that offer better protection for your specific needs. We believe in tailoring our gloves to your tasks, not the other way around. This not only ensures your hands are well-protected but also enhances your work efficiency.

So, join us as we delve into the intricate world of glove materials, uncovering the science behind them and understanding their role in our day-to-day work. We'll guide you on a journey through latex, nitrile, vinyl, and leather, and by the end, you'll have a firm grasp on what makes each material special in its own right.

The Science Behind Glove Materials

Materials selection for gloves is critical, as it can drastically affect their functionality and durability. The quality, durability, and protective properties of gloves largely depend on the materials used in their construction. Each material offers unique properties that are beneficial for specific purposes and environments.

Leather, for instance, is a common choice for cut & sew gloves, often used for its excellent durability and comfort. Various types of leather, both split and grain, bring specific qualities to the gloves. For example, cow leather is thick and durable, providing great durability. Goat and deer leather are thin, offering elasticity and dexterity, with deer leather providing increased comfort. Pig leather is highly abrasion resistant yet thin, while sheep leather boasts extreme thinness for best tactile sensitivity. Even kangaroo leather is a great choice for cut & sew gloves with its combination of thinness, durability, dexterity, and elasticity.

For gloves that require high tear strength and puncture resistance, woven materials like canvas, ballistic nylons, and puncture & cut resistant palm linings are utilized. The denier, the mass density of the material, is critical when choosing a woven material. The higher the denier, the higher the mass density, typically resulting in a thicker, more sturdy, durable and rigid material.

Knit materials, on the other hand, provide mechanical stretch and recovery, which makes them ideal for areas of motion. Common knit materials include nylon, polyester, HPPE, and Aramid.

Non-wovens encompass all other types that do not fall under the categories of woven or knit. Examples of these include synthetic leather, PU embedded materials, silicone embedded materials, and multi-layered waterproof or windproof materials. These materials offer a unique balance of flexibility and protection, making them ideal for a range of applications.

Different surface treatments can enhance the properties of these materials further. Water & oil repellent coatings like 3M Scotchgard, Dupont Teflon, and other PFAS / PFOAS help to shield the gloves from moisture and oily substances, extending their usability in challenging environments. Silicone printing, wax coatings for leather, and glass pellets for light reflectivity are also used to increase the performance, durability, and safety of gloves.

Seamless Knit Coated Gloves

When it comes to seamless knit coated styles, glove yarns are typically constructed from a combination of fibers like cotton, polyester, nylon, Aramids, glass, HPPE, elastane, stainless steel, tungsten, and carbon fiber. These fibers are spun together to create a yarn, which is then knitted to construct the seamless glove.

These gloves are prevalent, thanks to their production efficiency and versatility. Seamless knits are form-fitted with three-dimensional stretch, providing superior comfort and dexterity. The seamless construction also aids in cut resistance, and the coating variations ensure grip, durability, chemical and fluid resistance.

Pros:

- Comfort: Thanks to the form-fitted design with 3D stretch.

- Dexterity: Their cut resistance is due to the versatility of the fibers and yarn.

- Low Cost: Highly automated manufacturing process reduces labor.

Cons:

- Limited Materials: Unified construction limits strategic placement of differing materials.

- Design Constraints: Automated manufacturing process limits the number of differing operations that can be applied.

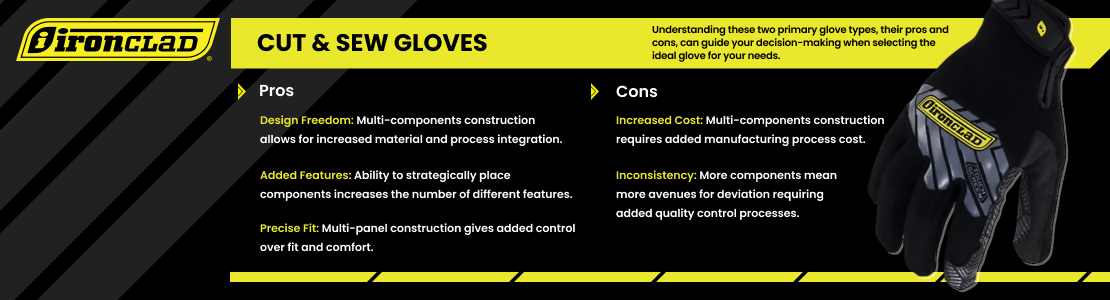

Cut & Sew Gloves

Cut and sewn gloves offer more flexibility in design and material use. They can incorporate knits, wovens, non-wovens, leather, and molded components.

Pros:

- Design Freedom: Multi-components construction allows for increased material and process integration.

- Added Features: Ability to strategically place components increases the number of different features.

- Precise Fit: Multi-panel construction gives added control over fit and comfort.

Cons

- Increased Cost: Multi-components construction requires added manufacturing process cost.

- Inconsistency: More components mean more avenues for deviation requiring added quality control processes.

Understanding these two primary glove types, their pros and cons, can guide your decision-making when selecting the ideal glove for your needs.

Types of Gloves and Their Specific Uses

Now that we've delved into the intricacies of glove materials, let's explore different types of gloves and the specific uses they're designed for.

Navigating the broad landscape of glove types requires understanding your specific needs. Ask yourself, "What type of glove do I need?" The answer depends on the functionality and characteristics you desire. Understand there is no “perfect glove”, every characteristic has a tradeoff.

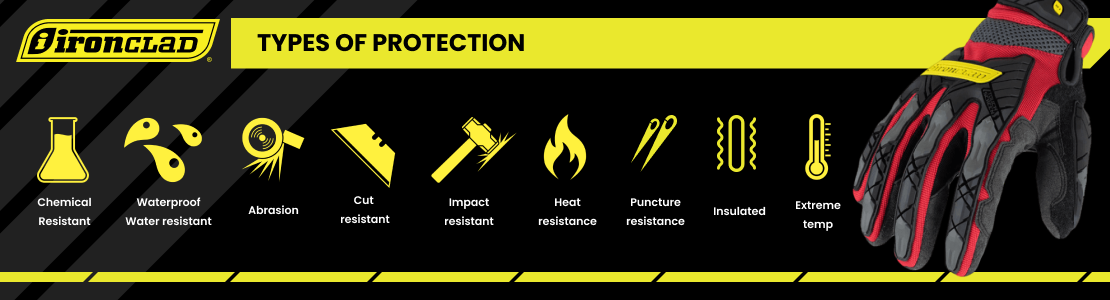

Comfort and dexterity are crucial for roles requiring fine motor skills. Gloves that offer excellent grip can enhance control over objects and tools, serving as a mechanical advantage. Protection is another key factor that comes in varied forms. Gloves can be designed for chemical and fluid resistance, including waterproof, water-resistant, or chemical-resistant types. This is vital for those in the chemical industry or healthcare sector. Abrasion and cut resistance are important in industries dealing with rough surfaces or sharp tools, respectively. If your work involves potential blunt impact or vibrations, consider gloves offering impact resistance.

Tear resistance extends glove lifespan in high-wear environments, while puncture resistance is vital when dealing with piercing objects, such as nails or needles.

Electrical workers may need gloves designed for electrical hazards. Those in high-temperature environments should consider gloves with heat protection, including contact heat, flame resistance, or arc flash protection.

Lastly, gloves for cold weather elements can be insulated, battery heated, or infrared reflective, keeping hands warm in harsh weather conditions. Understanding the purpose and functionality of different glove types ensures an informed decision based on your needs, promoting optimal performance and safety.

Understanding Glove Selection & Choosing the Right Gloves for Your Needs

Having gained an understanding of different glove materials and their respective uses, let's explore the process of glove selection. This process is more than just a matter of preference – it's about safety, efficiency, and ensuring that your hands are protected in the best possible way.

The first step in glove selection is identifying the potential risks and requirements of the task at hand. This might involve handling hazardous chemicals, exposure to sharp objects, working with hot or cold objects, or requiring a high degree of tactile sensitivity. Once these factors are identified, you can narrow down your options and look for a glove that meets these specific needs.

Next, consider the breakthrough time and permeation rate we discussed earlier. For example, if you are handling organic solvents, a nitrile glove would be a better choice than latex due to its higher resistance and longer breakthrough time.

Personal comfort is another critical factor. Remember that gloves should fit properly – not too tight that they restrict movement, and not too loose that they might come off. Ironclad offers a 16-point measuring system to ensure the right glove will allow for dexterity, comfort, and overall better protection. And let's not forget the importance of considering potential allergies to glove materials, such as latex.

If you're working in low temperatures, consider gloves designed specifically for cold weather. Many materials, like certain types of leather and synthetic materials, offer better insulation and keep your hands warm while working in such conditions.

Lastly, always remember that even the best glove cannot provide absolute protection. Regularly inspect your gloves for any signs of wear and tear or degradation, and replace them when necessary.

How Ironclad Performance Wear Innovates in Glove Material Science

When it comes to personal protective equipment (PPE), unwavering dependability and long-lasting durability define its true value. This is where Ironclad sets itself apart from competitors – an unwavering dedication to mastering the most formidable challenges in manufacturing and product design.

In the realm of Impact Protection, Ironclad thrives on the development of solutions that not only offer precise safeguarding but also uphold flexibility. Our proprietary design methodology ensures a meticulous equilibrium among the chemistry, hardness, and flexibility of our impact protection materials. This deliberate synergy, complemented by a streamlined manufacturing approach, enhances the reliability and effectiveness of our impact protection solutions.

Likewise, Ironclad embraces a proactive stance when addressing Cut Resistance. We recognize the inherent performance variability associated with cut resistance and the ripple effects stemming from even the slightest deviation in fiber production. To preemptively address this challenge, we establish close collaborations with our fiber and yarn suppliers, resulting in the creation of materials that are both predictable and dependable. Our finished products consistently carry conservative cut resistance ratings, aiming to surpass expectations, even under the most adverse conditions.

In our pursuit of excellence at Ironclad Performance Wear, we constantly push the boundaries of glove material science. We understand that every task is unique and demands specialized protective gloves. That's why we create high-performance, task-specific work gloves designed to cater to the individual needs of different industries.

Our approach is underpinned by an unwavering commitment to innovation, design, and advanced material science. We carefully research and select the right glove material for each task, ensuring a balance of durability, dexterity, and comfort. From natural and synthetic leathers used for heavy-duty tasks to nitrile and latex for handling hazardous substances, we always prioritize the safety of our glove wearers.

For instance, we recognize the need for gloves that can resist harsh chemicals without causing allergic reactions. In response, we've developed disposable nitrile gloves that combine the robust chemical resistance of nitrile with the convenience of disposable gloves. These gloves provide excellent protection against a wide array of substances, including oils and organic solvents.

Similarly, we've addressed the unique needs of tasks requiring a high level of tactile sensitivity and flexibility. Our range of latex gloves offers a snug fit and a high degree of sensitivity, making them an ideal choice for tasks requiring precision.

Understanding the risks of hand injuries in cold environments, we've also developed gloves designed for low temperatures. These gloves are crafted from materials that not only provide excellent protection but also offer insulation to keep the wearer's hands warm.

At Ironclad Performance Wear, our mission is to deliver high-quality, performance-oriented gloves that protect and empower individuals across various industries. We believe that the right glove, made from the right glove material, can enhance safety, efficiency, and productivity. It's this belief that continues to inspire us as we strive to create innovative, reliable, and performance-driven gloves that you can trust. Whether you're working in construction, handling hazardous materials, or needing protective gloves for any other task, you can count on Ironclad Performance Wear to provide the ideal hand protection solution.

Ironclad’s Glove Sustainability

Ironclad's unwavering commitment to sustainability revolves around a simple yet impactful equation: Durability equals Sustainability. By constructing durable products designed to withstand extensive use, we significantly lower replacement consumption, which in turn reduces costs and environmental impact.

Our gloves' durability is not just about robustness and long-lasting use, but also about reusability. Unlike many products in the market that are used once and discarded, most of our gloves are machine washable, further promoting our sustainability agenda.

While biodegradable gloves are gaining popularity, we at Ironclad make a strategic choice to avoid them. The reason lies in the inherent problem of biodegradable PPE – they are inherently unstable and readily degrade on the shelf, making it impossible to guarantee long-term performance and safety by the time it reaches the end user’s hand. For us at Ironclad, sustainability never compromises our core mission of delivering trustworthy, high-quality personal protection equipment to our users