IRONCLAD PERFORMANCE IMPACT TESTING

Posted by IRONCLAD PERFORMANCE WEAR on Feb 3rd 2022

BACKGROUND

In 2008, Ironclad introduced the world’s first Heavy Impact protection glove, the KONG Original. As several other impact gloves came to market in 2010, with varying levels of impact protection and hand coverage, large drilling companies began asking for a way to evaluate the protection levels offered by different impact glove styles. Although glove standards existed for abrasion, cut, and puncture resistance, none existed for impact protection.

To address this, Ironclad’s resident biomedical engineer, Eric Jaeger, teamed up with Dr Naira Campbell-Kyureghyan of the Biomechanics Laboratory at the University of Wisconsin-Milwaukee and set out to create a reliable, repeatable glove impact test. The requirements for this test included, simulation of real world impact forces, simulation of the biomechanical response of the human hand, measurement of impact forces at different zones covering the entire hand, establishing the determinant factor of blunt force trauma, and the determination of the protection level offered by a glove. Final results of this landmark study included complete impact testing protocols for weight, drop height, impact locations, sensor locations and force measurement techniques, creation of a biomechanically true ‘ballistic manikin’ hand, testing of the KONG Original glove at three zones - fingers, knuckle joints and metacarpal bones, determination that ‘peak impact force’ causes blunt force trauma, and the first-ever calculation of hand impact protection offered by a glove.

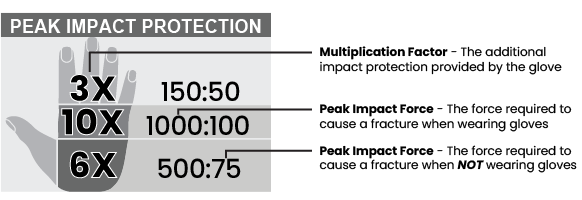

Ironclad introduced 18 impact glove styles between 2010 and 2015, and in the continuing effort to lead the hand impact protection field Mr. Jaeger and Dr. Campbell-Kyureghyan partnered again on a new impact testing study in 2015. In this study, testing was expanded to 18 different glove styles as well as human cadaver hands, which lead to the determination of the specific impact forces that cause bone fractures in the human hand. To summarize the results a new Impact Protection Symbol was created, which specifies the levels of impact protection provided to the hand when wearing a specific glove.

Peak Impact Forces resulting in a human hand bone fracture:

Fingers & Thumb: 50 lbs

Knuckles: 100 lbs

Metacarpal: 75 lbs

IRONCLAD PERFORMANCE IMPACT TESTING

Minimum bone fracture levels are determined by dropping a 7.6 kg (16.8 lbs) flat rectangular mass onto fresh cadaver hands from a range of heights, creating 15 to 37 J of impact energy. Whole glove testing is performed by fitting gloves onto a custom ballistic manikin hand, with sensors located between the glove and hand at the fingers, thumb, knuckles and metacarpal bones. A 7.6 kg (16.8 lbs) flat rectangular mass is dropped onto the glove-hand combination, resulting in 15 J of impact energy at each zone. Baseline testing is performed by dropping the same mass onto the ballistic manikin hand without a glove. Peak impact forces are recorded by the sensors at the glove-hand interface. Reduction in peak impact force and the impact protection factor at each zone are calculated.

Pros:

Cons:

IMPACT PROTECTION SYMBOL